In the year 2012, Marks & Spencer (M&S), a London based clothing and merchandise retailer decided to extend its RFID- tagging to all general merchandise. A few years earlier, the company had taken the initiative to look at RFID technology to track and manage apparel. The above lines leave no doubt that RFID has enabled a renowned global retailer to enhance efficiency of its operations and increase business success.

Today, the apparel and footwear industry is not just looking at technology for operational efficiency, it is increasingly interested in augmenting the customer experience by leveraging technology.

Shopping Redefined

Do you have to go to a shop today to buy what you need? Or is it delivered home and you pay from your mobile phones with just a click? Today, the apparel and footwear industry has to be equally appealing at the online marketplaces as at its stores. Omni-channel presence is of paramount importance and the experience for customers across channels has to be seamless.

Operational Enhancements = Customer Delight

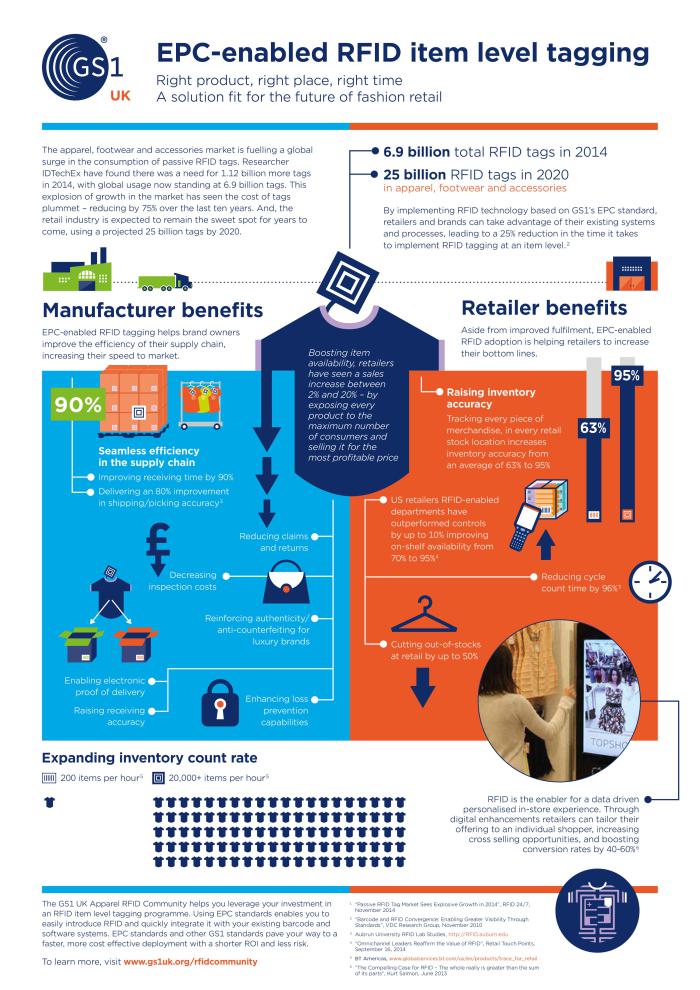

I will focus on operational enhancements owing to RFID implementation in the Apparel and Footwear industry. Over the last five years, the use of RFID has seen tremendous growth in the Apparel and Footwear industry. The two major factors responsible for this are the realization that technology can add value throughout the supply chain and the rise of channels (internet, mobility, marketplaces) for consumption of these products.

There are definite perceivable advantages in using RFID technology and I would like to discuss them in the succeeding paragraphs.

Better Inventory Accuracy:

The inventory accuracy in normal operations of a manually run inventory management system or a barcode run system can be as low as 60% going to a maximum of 75%. The use of RFID enhances the accuracy to about 95-99%. This ensures that there are no stock outs, better production planning and management, optimum utilization of warehouses, better managed supply chains and most importantly, delighted customers.

Reduction in Cycle Count Time

The process of physically checking the inventory is usually done either once or twice a year. Each time this activity is undertaken, it takes many hours, even days at times. However, the results are still never accurate.

In contrast, an RFID based stock can be checked daily, within a matter of hours. All you need is a person with a handheld RFID reader. This optimizes the labour cost, enhances inventory accuracy, reduces shrinkages due to complete visibility of stock and hence enhances the entire supply chain planning and associated costs.

Reduced Inventory Carrying Costs:

With better inventory tracking, management and accuracy in count, the inventory can be rationalised and hence reduced. The production can be aligned with the consumption and hence inventory is maintained to the minimum. This reduces the inventory storage and carrying costs and hence contributes to a healthier bottom line.

Reduced Receiving Time:

With customers preferring to try out various omni-channel options available to them, the expectation in terms of delivery has also gone up. With RFID tagging, stocks needn’t be checked manually at every point along the supply chain. Thus, the time taken to order and receive the goods is drastically reduced. This reduces stock-out situations and also minimises lost opportunities for product sale. This results in enhanced operational efficiency and improved bottom line – both very critical parameters.

Improved Conversion Rate.

With drastically reduced stock outs and total visibility of the stock at all levels i.e. shop floor, back stores, distribution centres and the factory warehouse, there will never be an instance where the customers has to turn back because the right size or design is not available. If this is not customer satisfaction, then what is?

Increased Sales:

With total visibility of stocks, better managed supply chains and optimum inventory, the sales are bound to increase and hence the revenue. Studies with various retailers such as American Apparel, Bloomingdales , Marks & Spencer etc. have shown that the increase in sales after RFID implementations has been in the range of 4% to 21%.

Prevention of counterfeiting:

One of the major benefits of using RFID for branded products is the prevention of counterfeiting. With the advantage of unique identifier numbers, counterfeits can be easily identified and eliminated from the roots thus enhancing the brand value of the products. This is especially beneficial as it stops the counterfeit from getting through and reaching the customer. If it does, you will not only lose a customer for life but he may also influence a number of other loyal customers through the use of social media and other forums. Hence, by eliminating counterfeit products, RFID technologies enable to avert a potential PR crisis.

Theft prevention:

Shrinkages in the stock due to shop lifting by customers and also by the staff can be almost eliminated by use of RFID. Unlike the traditional EAS systems, UHF RFID tags serve both the purposes – inventory management at store shop level and also the EAS activity. Any unauthorised removal of stock from the stores is immediately detected and identified thus acting as a deterrent.

Data Analytics and strategic decisions:

If the data from RFID tracking is collected and studied, it can reveal trends, patterns and insights which can further improve operational efficiency and enable to make better strategic decisions. Big Data analysis is the future for the Retail industry in general and Footwear & Apparel in particular.

Implementation of RFID

While the advantage of implementing RFID for Apparel and Footwear industry entities is evident, it is important to get it done in a structured and phase-wise manner.

The following steps will enable seamless RFID implementation:

- You should choose a company who has proven capabilities, is cost-effective and can implement RFID in a structured manner

- The company can first do a limited proof of concept (POC) covering the delivery centre and a couple of stores

- Once the processes are identified and implemented in a couple of stores, the lessons can be then be used to roll out the RFID over the complete network of the brand.

We, at Dolphin RFID, provide end-to-end solutions in RFID. Through the above steps, we can ensure a seamless RFID implementation for companies in Apparel and Footwear. We also provide best in class after sales service through the life cycle of the product. If you think RFID is the way to go, please do reach us out.

The objective of this blog and some of my subsequent ones would however, be to educate the users across industries on the benefits of RFID technologies. If you come across ambiguities while considering RFID for your business, I would be happy to have a detailed discussion.